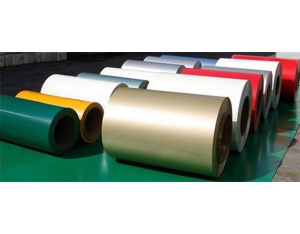

More and more decorative aluminum coils are appearing in people's daily lives in the market. Surface treatment of aluminum coils can improve the decorative, corrosive, and functional properties of products. As a professionalAluminum coil manufacturerWe have advanced technology and a deep understanding of aluminum coils.

1. Pre treatment, first use methods to clean the surface, using both physical and chemical methods, and the most important thing is toInsulated aluminum rollExpose the substrate. This is conducive to the complete progress of oxidation, and the formed oxide film will also be dense. Pre processing can also be done using some mechanical equipment.

2. Anodizing, after treatment with the insulated aluminum coil, causes the substrate to undergo an anodic oxidation reaction, which then generates a dense oxide film.

3. Sealing, after anodizing, many film pores will appear on the oxidized film. Sealing is to seal these film pores and prevent contamination of the oxide film. This oxide film is transparent and has adsorption properties, which can deposit some metal salts in the pores, revealing some of the original silver white or many other colors on the surface.

Through these steps, we can understand that aluminum coils are colored through these processes, making our buildings more colorful.