Aluminum coil manufactureranalysisInsulated aluminum rollThe pressing process of.

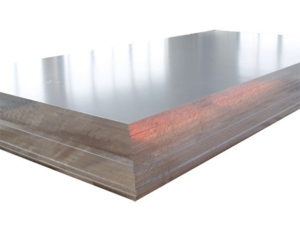

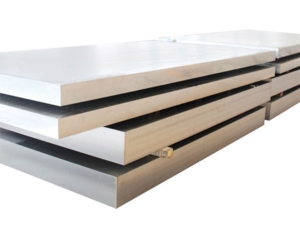

Pressing refers to the process of pressing insulation aluminum coils into various types through pressing equipmentPressed aluminum plateOr corrugated aluminum plate, including light aluminum roll forming andColor coated aluminum rollPressed, products are widely used in equipment insulation, roofing, and wall surfaces

The insulation aluminum coil and color steel coil use universal molding equipment, and through the pressure processing of the molding equipment, various types of pressed aluminum plates will be formed in the future. The aluminum coil needs to be softened and treated in H24 condition to ensure that the compression does not crack. In fact, the compression is similar to bending, and through the compression, the strength will increase, which can be used on building roofs and also become roof insulation aluminum plates

During the molding process of insulated aluminum coils, attention should be paid to the distance between the equipment. Cracks should not appear during the molding process due to the small distance. At the same time, attention should be paid to organizing the equipment without oil, dust, and gold particles to ensure the surface smoothness and scratches of the insulated aluminum coils after molding

Insulated aluminum coil is a metal product that is processed by casting and rolling mill through rolling, bending, and angle cutting, and then used for flying shear. With the development of technology, it has been widely used by people. Due to the increasingly widespread use of insulation aluminum coils, the variety of products sold in shopping malls is also different, and the price is also unstable, which constitutes insulationAluminum coil priceWhat are the elements of fluctuating high and low?