PVDF fluorocarbon sprayed aluminum coil | Colorful coated aluminum coil. The paint surface of this aluminum coil has a delicate texture, uniform color, bright colors, and is constantly new. It is particularly suitable for high-end decoration projects such as outdoor, roof, curtain wall, and suspended ceiling,Color coated aluminum rollThere are various types of colors available, which can be adjusted according to customer requirements or samples.

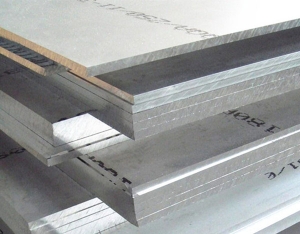

Different coatings have different thickness requirements, and the general primer should be controlled at 7 μ Around m, the topcoat should be ≥ 25 μ m. Varnish 15 μ About m. Due to the difficulty in measuring the thickness of each paint layer in the final finished product, the standard only specifies the average thickness of the total coating and the local minimum thickness. The requirements for the thickness of each paint film should be controlled by the enterprise in the process. The testing of weather resistance in AAMA2605 uses the sun exposure method, which is not only economically burdensome but also takes too long (10 years).

Therefore, this standard adopts the method of simulating the artificial accelerated aging test of dense lamps with superior sunlight performance and acceleration for verification. The compatibility with structural adhesives and sealants is a safety issue that should be highly valued by both the supply and demand sides. The supplier should provide relevant compatibility information for the reference of the supply and demand side. When using the products specified in this standard, the purchaser should consider their compatibility when selecting structural adhesives and sealants, and if necessary, conduct compatibility tests. This standard is proposed by the China Non ferrous Metals Industry Standard Metrology Quality Research Institute. This standard is under the jurisdiction of the China Institute of Metrology and Quality for the Non ferrous Metals Industry.