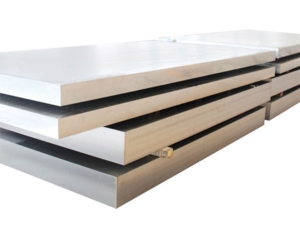

Aluminum alloy plate,

As the name suggests, it refers to a plate shaped material made of aluminum alloy or aluminum alloy material. That is to say, it is a sheet shaped aluminum product manufactured by heating, rolling, straightening, or solution aging heat treatment of flat aluminum embryos.

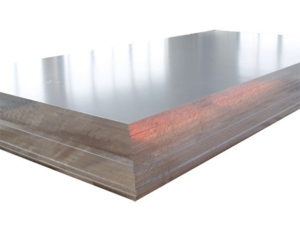

The aluminum alloy plates used in buildings include single sided aluminum alloy plates, composite aluminum alloy plates, and other materials. They usually refer to single sided aluminum alloy plates (also known as single sided aluminum alloy plates or 1060 aluminum plates), which are mostly used in construction decoration projects. In recent years, single sided aluminum alloy plates have been more commonly used in aluminum single panel curtain walls. Aluminum veneer curtain walls are also a form of building curtain walls, which can be simply described as using aluminum alloy plates instead of glass windows to make building curtain walls. Aluminum veneer curtain walls are mostly used for wall shielding and non lighting walls.

For example, at the Guangzhou World Trade Center, nearly 150 tons of aluminum alloy plates with different radians were processed by the Southwest Aluminum Processing Plant's Plate Branch, and the surface was coated with electrostatic spray molding. Single sided aluminum alloy panels have always been used for aluminum veneer curtain walls in foreign countries. Single sided aluminum alloy plates are commonly used with 1060 aluminum plates. The thickness of the aluminum alloy plate is 3mm in order to enhance the surface strength of the aluminum alloy plate. On the opposite side of the aluminum alloy plate, a rib plate must be installed (which is not safe for existing manufacturers). The rib plate is made of thick aluminum strip, and first a shiny brazing and hot melt welding machine is used to pad and weld screws on the opposite side of the aluminum alloy plate. Then, the aluminum strip used as the rib plate is drilled and inserted into the screw thread, and fixed with the screw thread. In order to reduce the weight of aluminum alloy plates and increase their strength in China, we use aluminum alloy plates. We often choose aluminum alloy plates made of No. 21 rust resistant aluminum code LF21 as building curtain wall aluminum alloy plates. The thickness of aluminum alloy plate has been reduced from 3mm to 2.3mm, and the strength of this alloy is several times higher than that of 1060 aluminum plate. The rib plate is made of LF21 aluminum strip, and the net width and thickness of the aluminum strip are determined based on the surface of the aluminum alloy plate, usually with a thickness of 2-2.3mm and a width of 10-25mm. The aluminum alloy plate on the reverse side of the aluminum veneer curtain wall does not need to be reinforced. Under external positive and negative pressure, the aluminum alloy plate is not prone to dents and bulges, thus avoiding the vibration sound generated by repeated internal and external vibrations of the aluminum veneer curtain wall. If sound insulation and insulation are required, rock wool, slag wool, or foam treatment can be placed on the inner side of the aluminum alloy board. The first aluminum veneer curtain wall in ChinaAluminum plate manufacturerChongqing Southwest Aluminum Deep Processing Factory, a military manufacturer, can produce aluminum alloy plates with a net width of 2.8 meters.

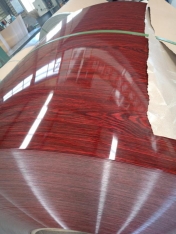

The metal surface treatment of aluminum alloy plates for building curtain walls can be divided into two methods: anodizing and electrostatic spraying. The anodized oxide film is usually at 12 μ Above, there are only two colors available: bronze and white, which are monotonous in color. The more serious drawback is that the surface color of each aluminum alloy plate varies in depth, and many building curtain wall panels together create an overall unattractive effect on the building curtain wall. This disadvantage can be said to be irreparable, not due to technology, but rather because aluminum alloy plates are not made up of a single batch number and have small differences in chemical composition. In addition, factors such as the current density of the electrolytic cell solution during oxidation cannot be completely the same. Therefore, the color differences after oxidation may not be obvious on a single sheet, and if they are all arranged together, they will be very obvious. Therefore, anodizing is not allowed for the metal surface treatment of aluminum alloy plates in aluminum veneer curtain walls.

Another method of metal surface treatment for aluminum alloy plates in building curtain walls is electrostatic spraying. Spray painting can be divided into powder spray painting and liquid spray painting. The main materials for powder spray paint are: polyurethane, polyexpanded resin, epoxy resin, etc